Test 1 - Compression Test whilst Cranking

A Compression Test whilst Cranking is a non-invasive procedure that detects low compression in a cylinder.

The engine should be prevented from starting (e.g. disable the injectors or fuel pump).

- Software: PicoScope 6 - Guided Test AT004

- Purpose of Test - Suspected Compression Issues

- Skill Level Required - Very Easy

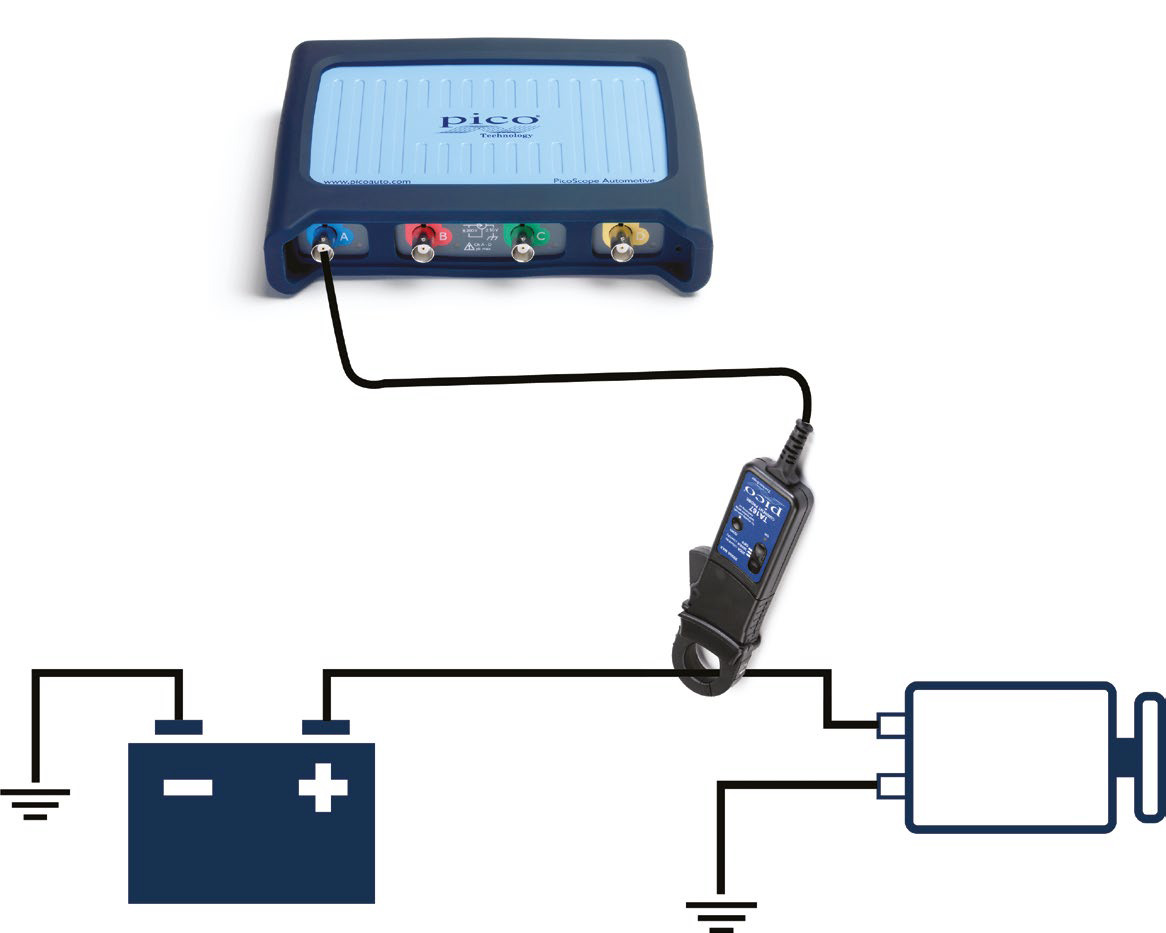

Connect: 2000 A Current Clamp – fitted around the battery+ cable. Make sure that the orientation of the clamp is correct with respect to the current flow away from the battery.

Run: Timebase should be set to 200 ms per division. Start PicoScope.

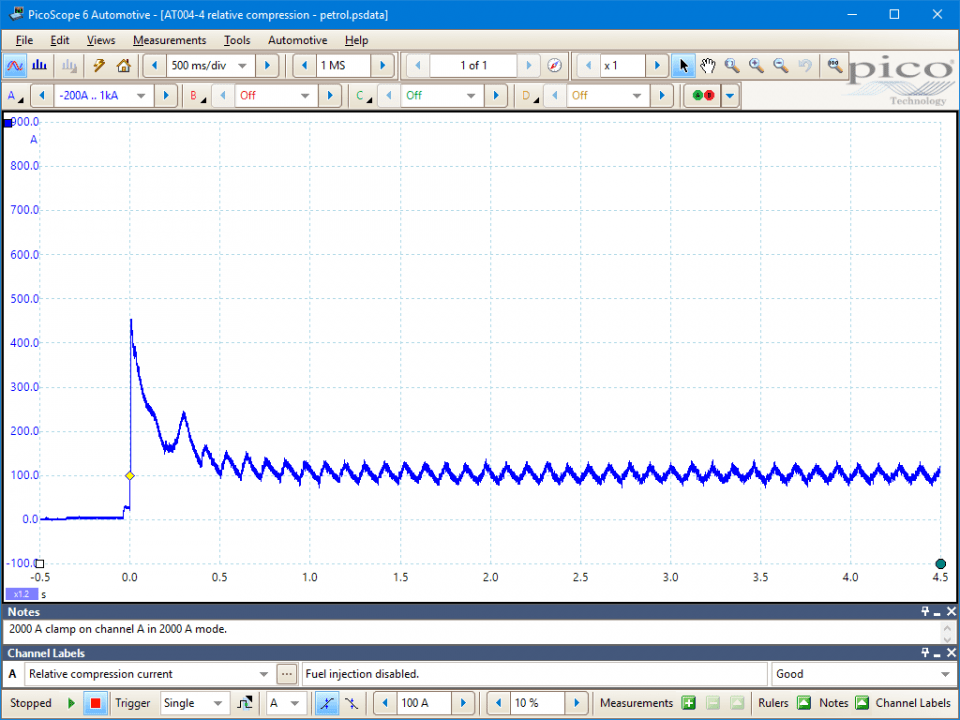

Read: The waveform shows the amperage to crank the engine, usually between 80 and 200 amps.

Once the engine has overcome the initial friction and inertia, the waveform should settle down to a consistent ‘sawtooth’ pattern – zoom and rulers can help evaluate here, although a drop in cylinder compression is often quite obvious.

If the waveform confirms a cylinder is losing compression, further testing with a low amp current clamp connected to an injector or ignition coil, or a COP probe to detect when the offending cylinder is firing, will help to identify the offending cylinder.

You can also use our WPS500X Pressure Transducer to highlight any mechanical issues requiring further attention by graphing the cylinder's internal pressure as the engine turns.

Waveform Analysis

The (good) waveform above shows even cylinder pressure peaks. Compare it with the waveform in the video below where one cylinder has low compression.

Notice the first (relatively tiny) increase in current at about -0.35 seconds when the ignition was switched on. Then notice the next bump at about -0.05 seconds when the current was applied to the bendix.

The fast rise at 0 seconds is due to the bendix contacts closing about 50ms later (which triggered the scope).

Current consumed by the starter motor increases with load. There is a large spike of current of about 450A which is due to the starter motor having to overcome the engine's initial inertia as it starts turning. This waveform is probably generated by a petrol engine. Diesel engines have much higher compression and therefore the start current is usually much higher.

The initial current drops quickly as soon as the engine starts turning. The sucession of peaks is due to each cylinder compressing, in turn. You are looking for all peaks to be roughly equal. Any discrepancy is cause for concern.

Compression Test Animation

Video Commentary

In this Compression Test animation, an exhaust valve on Cylinder 1 is not sealing properly (valve-stem bent).

Connect: Use your 2000A current clamp and connect it to Channel A of the PicoScope. If you have the new 4225A or 4425A scope, you can use the new PicoBNC+ PICO-TA388 Current Clamp. PicoBNC+ allows the scope to automatically identify the clamp and sets up the scope automatically saving you time and reducing errors. Fit the clamp around the battery+ cable. Make sure that the orientation of the clamp is correct with respect to the current flow away from the battery.

Prevent the engine from starting. There are a number of ways to do this such as disabling all of the injectors. In this example, the fuel pump fuse is removed which prevents fuel from reaching the engine.

Run: Crank the engine.

Read: Notice the initial high current peak as inertia is overcome. As the engine compresses, the starter motor has to work harder and it consumes more current. In this example, every fourth current peak is missing indicating a lack of compression in one cylinder. Stop cranking when you have sufficient data.

Connect: Connect a COP probe such as the new PICO-TA398 PicoBNC+ COP Probe to channel B. Again, PicoBNC+ will setup the scope automatically.

Run: Crank again.

Read: Notice the ignition events displayed in Channel B. The ignition event corresponds to a compression peak near TDC of the cylinder being probed. Use the firing order to identify the bad cylinder.

Guided Compression Tests on the Pico Auto Website: Diesel and Petrol.

Please click Next for the second test - Coil on Plug (COP) Test.