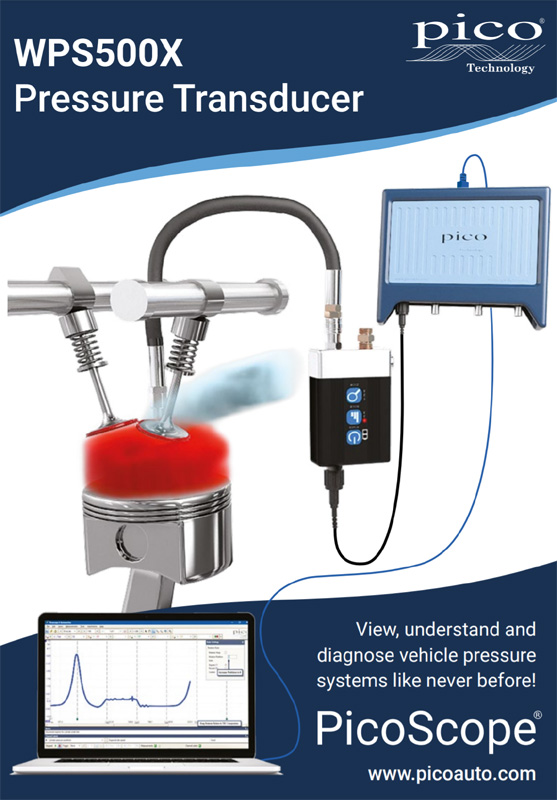

WPS500X Pressure Transducer

With the unparalleled resolution and accuracy of the WPS500X Automotive Pressure Transducer you can perform a quick and accurate pressure analysis of many automotive systems.

Overview

There are many potential causes for a particular problems reported by a customer, and simply reading fault codes leaves you no closer to a solution.

The PicoScope provides comprehensive electrical testing. Adding a WPS500X pressure transducer provides you with a more detailed insight into the engine system. Accurately diagnose common problems such as:

- No start

- Loss of power

- Misfire

- Stalling

- Engine noise

- Emissions fault

- Backfire

The unparalleled resolution and accuracy of the WPS500X Automotive Pressure Transducer allows you to perform quick and accurate pressure analysis on many automotive systems.

- Accurately measure up to 500 psi or 34 bar

- Ultra-fast 100 µs response time

- Zoom function for enhanced analysis capabilities

- Internal rechargeable LiPo battery

- Integrated pressure relief / bleed-off valve

- Auto zeroing

- High noise immunity

- Temperature compensated

Your WPS500X features an extremely fast 100 µs (0.0001 second) response time from 0% to 90% of full scale and sensitivity down to about 0.07 psi (5 mbar). This provides you with an accurate representation of rapidly changing pressures that span a broad range.

Use the WPS500X with PicoScope to reveal how your engine is actually performing with minimal intrusion. Compression, airflow, valve timing and back pressure can all be measured in one hit.

Ranges

A WPS500X has three pressure ranges to allow accurate measurement and analysis of many automotive pressures including cylinder compression, fuel pressure, intake manifold vacuum and even pulses from the exhaust.

| Range | Pressure range | Accuracy | Response time | Output scaling |

|---|---|---|---|---|

| 1 | –15 to 500 psi –1 to 34.47 bar |

1% of scale | 100 µs | 10 mV/1 psi (500 psi = 5 V) |

| 2 | –15 to 50 psi –1 to 3.45 bar |

1% of scale | 100 µs | 100 mV/1 psi (50 psi = 5 V) |

| 3 | –5 to 5 psi –0.34 to 0.34 bar |

5% of scale | filtered | 1 V/1 psi (5 psi = 5 V) |

Range 1 (High Pressure)

Range 1 gives you high resolution and accuracy for high-pressure tests such as cranking and running cylinder compression or fuel pressure testing. Not only is this test a great way for you to find compression issues, but it is also an excellent way for you to identify cam timing issues such as jumped timing belts and stretched timing chains — this is especially useful on multi-cam engines that may not have a cam sensor on each camshaft.

Range 2 (Medium Pressure)

The second range measures from –15 to 50 psi (approximately –1 to 3.45 bar). This range is ideal for vacuum tests and fuel system tests. When testing these systems you will find the zoom function is especially useful as it makes it easy to analyze the valves operating with the vacuum waveform, or the injectors through the fuel waveform.

Range 3 (Low Pressure)

With the third range you can measure –5 to 5 psi (approximately –0.34 to 0.34 bar). This setting is sensitive enough to allow you to analyze small pressures or pulses such as pulses from the exhaust.

Zoom

The zoom function operates by removing all of the voltage from the signal below 100 Hz and then multiplying the remaining signal up to 100 times. For example: Let’s say your transducer is connected to the intake manifold vacuum on a running engine at idle with the transducer set to mode 2 (–15 to 50 psi) and the waveform on your PicoScope is at –9 psi. Fluctuations in the signal caused by the valves opening and closing versus atmospheric pressure forcing air into the manifold will be visible, but will only make up a small portion of the overall signal.

Selecting the zoom function will bring the waveform up to the zero line and the fluctuations will be magnified making an analysis of this component of the signal much clearer.

Nothing compares to the WPS500X

It is not unusual to require a different pressure transducer for each diagnostic test you want to run. The WPS500X eliminates this need by giving you one ultra-high resolution transducer that can be used for a multitude of automotive diagnostic applications. With three pressure ranges, a zoom function, pressure relief valve and a rechargeable Li–Po battery all enclosed in a durable housing the WPS500X is the cost-effective answer to pressure analysis.

When price, performance and versatility matter, there is nothing that compares to the WPS500X Automotive Pressure Transducer.

Tests

The pressure transducer has become the essential diagnostic tool to assist with a multitude of pressure related tasks from -15 psi up to 500 psi (-1 to 34 bar), so replacing the majority of analog gauges used today. With the ability to measure pressure against time we can now witness rapid events taking place that were never previously visible. Below is just a selection of how the pressure transducer takes diagnostic to a whole new level. (Adaptors will be required - please explore our comprehensive WPS500X kits).

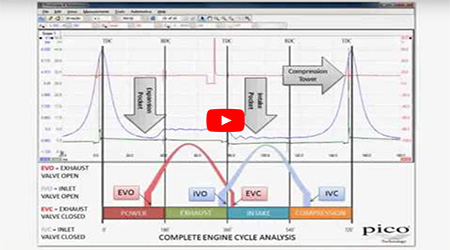

- In-cylinder pressure tests

- 4-stroke cycle visibility

- Exhaust gas pulsations

- Intake manifold pressure fluctuations

- Crankcase pressure measurements

- Diesel injector back leakage tests

- Fuel pressure tests up to 500 psi

Example Tests

Engine

- Cylinder compression testing (Cranking)

- Cylinder compression testing (Idle)

- Cylinder compression testing (WOT snap test)

- Intake manifold pressure petrol and diesel

- Exhaust gas pressure pulsations

- Exhaust back pressure evaluations

- Crankcase pressure pulsations

- PCV valve operation when you have high crankcase pressures

- Camshaft timing evaluation (Belt, Chain and Gear Driven)

- Cylinder head valve sealing integrity

- Engine oil pressure testing

- Cooling system pressure evaluation-Head gasket failure

- Radiator cap evaluation with over pressurized cooling systems

- Vacuum pump efficiency

Fuel

- Fuel delivery pressure, Petrol

- Fuel pressure regulator test, Petrol

- Fuel delivery residual pressure test, Petrol

- Fuel delivery/priming pump efficiency, petrol and diesel

- Fuel positive priming pressure, Diesel

- Fuel negative priming pressure, Diesel

- Fuel delivery residual pressure, Diesel

- Fuel injector back leakage test, Diesel

- Fuel injector contribution evaluation test, Petrol

- “Evaporative loss” control vacuum circuits and solenoids

Turbo Charger

- Boost pressure evaluation (Variable vane errors)

- Boost control vacuum circuits and solenoids

- Waste gate operation

Engine Management

- Variable induction system actuator/control integrity test.

- Idle control damper integrity test.

- Cruise control actuators, vacuum circuits and solenoids.

Chassis

- Air suspension pump efficiency

- Air suspension residual pressure testing

- Air suspension control pneumatic circuits & solenoids

- Brake servo evaluation and integrity test

Transmission

- Auto transmission line pressure testing

- Auto transmission governor pressure testing

Mechanical

- Cylinder head gaskets

- Broken or stuck rocker valves

- Blocked exhaust / Diesel Particulate Filter (DPF)

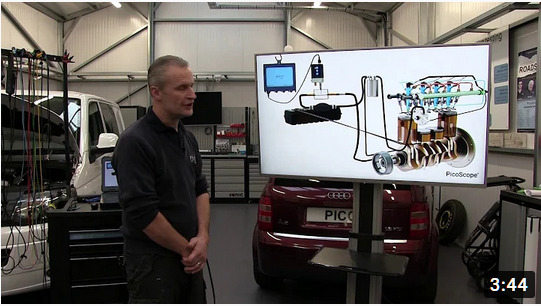

Watch - OilPressure

Steve shows us how to measure oil pressure with the WPS500X pressure transducer, showing us how to connect to the system and how to perform the test.

Steve shows us how to measure oil pressure with the WPS500X pressure transducer, showing us how to connect to the system and how to perform the test.

Watch - Intake Manifold Pressure

Steve is here to show us how to test the intake manifold pressure during cranking with the WPS500X pressure transducer.

Steve is here to show us how to test the intake manifold pressure during cranking with the WPS500X pressure transducer.

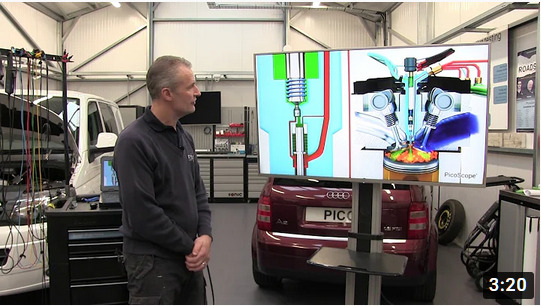

Watch - Diesel Back Leakage Testing

Steve shows us how to connect and test the diesel back-leakage with the WPS500X. You will see an animation of the system's operation and how it affects the waveforms.

Steve shows us how to connect and test the diesel back-leakage with the WPS500X. You will see an animation of the system's operation and how it affects the waveforms.

Watch - DPF Back Pressure Testing

Steve shows us how to test Diesel Particulate Filter backpressure with the WPS500X. You will see an animation of the system's operation and how it affects the waveforms.

Steve shows us how to test Diesel Particulate Filter backpressure with the WPS500X. You will see an animation of the system's operation and how it affects the waveforms.

Watch - Testing negative priming

Steve shows us how to check the negative diesel priming with the WPS500X. You will see an animation of the system's operation and how it affects the waveforms.

Steve shows us how to check the negative diesel priming with the WPS500X. You will see an animation of the system's operation and how it affects the waveforms.