FirstLook Engine Diagnostic Sensor

The FirstLook Engine Diagnostic Sensor offers a fast and accurate method to diagnose automotive engine problems such as burnt valves, bad injectors and other performance problems without major disassembly of the engine.

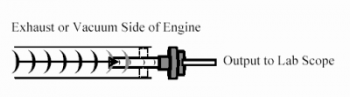

When connected to the exhaust or vacuum side of the engine to be tested the FirstLook engine diagnostic sensors enables a mechanic to display a complete picture of core engine performance quickly on a suitable digital storage lab scope.

The FirstLook sensor requires no external power source and is particularly suitable for use with a PicoScope but can also be used with most other modern lab scopes.

How does it work?

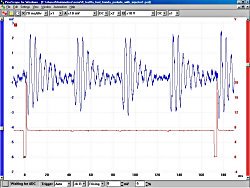

The FirstLook sensor looks at the pulse waves generated by the normal operation of an internal combustion engine. All engines produce a predictable pattern of these pulses and so any change or irregularity in the pulse wave can be traced back to problems in the engine. The pulse wave can also be affected by unburned fuel in the exhaust and this abnormality is also detected and displayed.

In typical use the FirstLook sensor is either placed in the exhaust pipe or attached to a vacuum port where it detects the air stream pulse waves. When connected to a suitable dual trace oscilloscope the display shows in real time the valve, cylinder and injector activity in any two or four stroke, gasoline or diesel internal combustion engine.

By displaying timing triggers on the scope, observed malfunctions may be pinpointed to specific cylinders. The ability to identify the specific cylinders where valve or injector problems are occurring greatly reduces the time and expense required to diagnose engine problems.

Examples of waveforms captured using the sensor are available at the Pico Library of Automotive Waveforms.

Innovation Award

Professional Tool & Equipment News (2004)

SenX Technology introduces their FirstLook™ Automotive Engine Diagnostics Sensor. According to SenX, when used with a dual trace lab scope, the new tool performs like an engine analyzer, providing performance data on engine cylinders, valves and injectors without any engine disassembly.

When an engine turns over, it generates an exhaust pulse every time a valve opens. FirstLook is connected to the tailpipe to analyze these pulses and capture data relative to how the engine and, more specifically, each cylinder is performing. The company feels comparisons can then be made between the different engine compartments to help determine if and where a problem exists.

To see just how well FirstLook would perform in the shop, we gave a unit to Innovation Award Panelist and ASE-certified Master Technician Mike Steptoe, owner of Reliable Auto Repair in Fort Atkinson, WI. His thoughts follow.

The Review

“I really liked this unit, especially the sensitivity it offers in capturing information on each cylinder. By looking at the wave patterns on my scope, I could definitely see when each individual valve was opening and closing. I also really enjoyed how quick and easy it was to set up, especially in comparison to a traditional engine analyzer. In less than 5 minutes I was ready to go, as there's only one connection. This is in comparison to the multiple test lead connections an analyzer requires.”

“Additionally, I'd think this would be an excellent tool for selling injector cleaning services, as you can see when the injectors are opening and closing. I was also able to diagnose some of the more difficult vehicle makes we get here. For me that meant I didn't have to turn away a Mercedes, but was able to diagnose and repair an injector problem. I think the ability to connect to a PDA also makes the tool a more economical alternative for an individual technician.”

Kit Components

The FirstLook Engine Diagnostic Sensor kit comprises of the following items:

- FirstLook Diagnostic Sensor

- 25 foot cable - BNC to BNC cable

- 45 inch cable - BNC to banana jack plugs

- BNC to BNC adaptor

- Vacuum line adaptor