An Introduction to Diagnostics

This article discusses how PicoScope Oscilloscope Diagnostics fits into the repair process.

Watch the animation (video) below.

Customer Interview

Let's start with an example:

A customer arrives at your workshop with an engine running issue. The first step is to ask the customer about the problem. A dashboard warning light (e.g. engine) often, but not always, alerts the customer to a problem requires attention.

OBD Diagnostics Fault Code

Your next step would probably be to attach a serial diagnostic or OBD tool to the vehicle.

You may see fault codes being returned, such as:

- P0016: Crankshaft Position - Camshaft Position Correlation

- P0345: Camshaft Position Sensor "A" Circuit; and

- P2614: Camshaft Position Signal Output Circuit/Open

You might therefore assume that the most likely cause of these codes would be a faulty camshaft sensor.

Replacement did not cure the fault

The camshaft sensor was replaced, the fault code erased, and the vehicle returned to the owner. However, in this example, the customer returned the next day with the same fault.

Using PicoScope Diagnostics

The simplistic senario above is all-too-often true. Lets consider a workshop equipped with a PicoScope. The astute technician would connect a PicoScope to the camshaft sensor output to test it before replacing it. The technician might also connect another channel to the crankshaft sensor to compare the two signals. Oscilloscope Diagnostics provides you with a much clearer picture of what is happening.

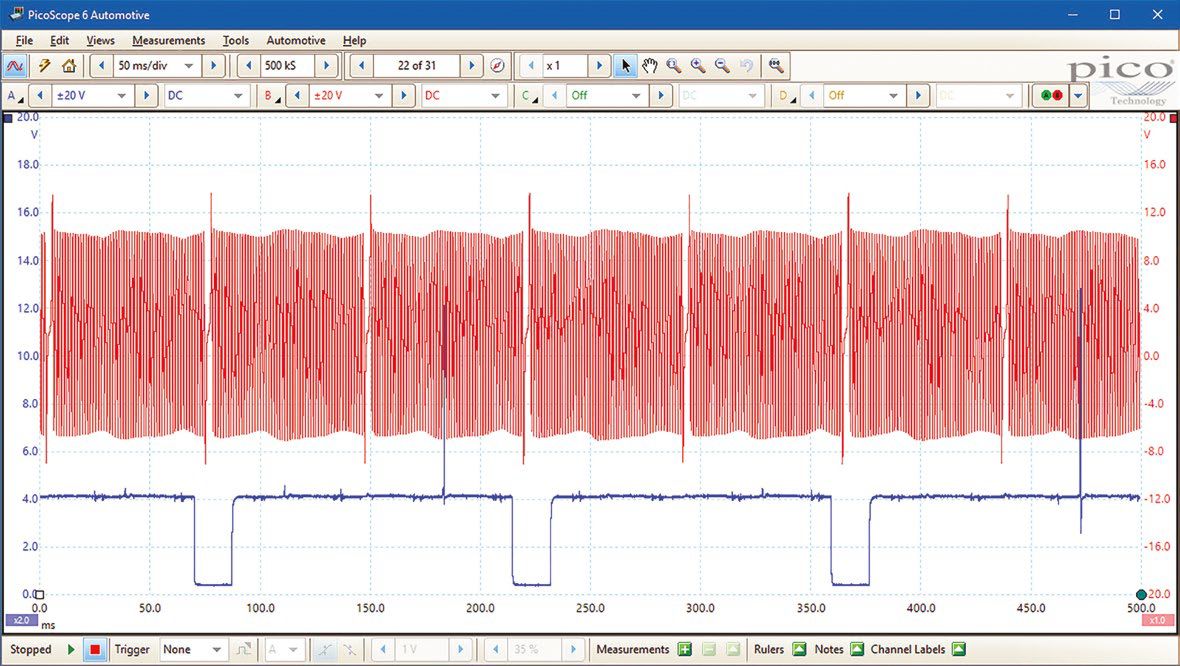

Cam / Crank Signal

The red crankshaft signal (inductive sensor) clearly shows the missing tooth used to index the rotation. The blue camshaft repeats (in this case but not always, one pulse) every second revolution of the crank. So far, everything looks good - there seems to be valid crank and cam signals! What could be wrong?

The technician wiggles the wiring and notices that the canshaft signal drops-out intermittantly as he does so. It follows that it is a wiring fault and the camshaft sensor is actually fine. A quick inspection finds that chafing of the cam signal wire in the loom caused it to wear through and the technican was able to repair the fault easily and without replacing the good camshaft sensor.

The animation below shows the scenario.

This new series of videos features the brand new 4425A and 4225A PicoScope with PicoBNC+.

Verification of the Repair

Following the wiring repair, the test was repeated with a PicoScope. The scope showed a clear fix. The fault codes were erased and the vehicle was returned to the customer. The workshop was confident that the root cause had been found and fixed.

Professional Service for your Customers

The customer left the workshop, happy after a successful repair. With no fault recurrence, this professional diagnostic workshop ensured future business with their customer. This is of course just one example of where PicoScope fits in the diagnostic journey. As technicians, you will understand there are many tools at your disposal, including technical information, training, knowledge, serial diagnostic tools, gas analyzers, and of course your PicoScope.

To find out more about how PicoScope can benefit your workshop and business, please click Next.